Product information

*Even for the same vehicle model, it may not be possible to install the product depending on the grade and year. In addition, additional parts may be required for installation. Please be sure to check the detailed compatibility with theHerePlease check more details.

---------------------------

Click here for the Motion Control Beam FAQ page >>>

---------------------------

The front and rear ends of the body are reinforced to increase torsional rigidity. The high rigidity body vibration is controlled by an ultra-high damping friction damper, creating the best street ride feel with strength and flexibility. Set of 2 for front and rear.>>Learn more

---------------------------

The ends of the body are reinforced to increase torsional rigidity.

Motion control beam with built-in friction vibration damper.

For active driving enjoyment, the stronger the body, the better. This is because the body distorts when the road surface exerts force on it, hindering the movement of the suspension... Of course, mass-produced car bodies have evolved year by year, and while they are now rigid enough for normal driving, there is still room for improvement in rigidity to fully enjoy the sense of unity with the car. That is why we have been searching for the weak points of mass-produced bodies and have been developing a lineup of products ranging from strut tower bars to full-fledged brace kits, aiming for the perfect rigid body.

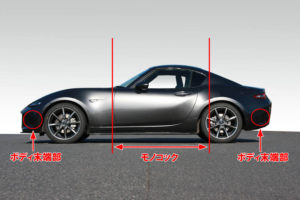

In an effort to go even further, the team focused on reinforcing the front and rear ends of the body to prevent twisting. Compared to the cabin in the center of the body where the monocoque is formed, the body is basically constructed of two "U"-shaped closed cross-section side frames laid out vertically, like the ladder frames used in trucks, and only has reinforcement placed on it. Moreover, since it is also where the suspension is attached, which is subject to heavy loads, it is more prone to twisting than the center of the body. If this area could be reinforced, a stronger body could be realized.

We previously developed a product called the Frame End Brace. Its structure is completely rigid, with the L-shaped structure fastened with high-rigidity steel oval pipes. By combining it with a strut tower bar and floor crossbars, we were able to significantly improve torsional rigidity. However, as the body becomes closer to being a perfectly rigid body, it becomes easier for minute vibrations from the road surface that cannot be absorbed by the suspension, tires, or rubber bushings to be transmitted. This tendency is particularly evident in the latest Mazda vehicles, which have high body rigidity.

To solve this problem, the Motion Control Beam (MCB) was developed.*1". In order to suppress micro-vibrations while increasing rigidity to the very limit, the parts that previously used the steel oval shaft have been changed to ultra-high damping friction dampers. The inside has a simple mechanical structure consisting of disc springs and friction plates, as shown in "Internal structure of MCB (conceptual diagram)".

First, the body rigidity is ensured by the tension of a strong disc spring with a spring constant 100 times that of a suspension spring. Then, the elasticity and friction of the friction plate suppresses the vibration from the stroke range at the moment when the body is about to vibrate. The stroke amount is only about 4um (=0.004mm) in a scene (0.5G) where a driver enjoying driving drives through a winding road at a high pace. Although it is a minute value that cannot be detected by measuring instruments, people judge the difference as a difference in the "ride feel". That is why we continue to focus on "sensation tuning" that does not appear in the specifications. We are expanding our lineup with new items that have both strength and flexibility. We want you to experience the effect for yourself.